Warehouse Management

.png)

.png)

Say goodbye to warehouse chaos

Are you tired of losing track of your products? Do you spend too much time searching for items or dealing with shipping mistakes? A Warehouse Management System (WMS) is the answer.

Better Inventory Control

Instead of relying on paper lists or complex spreadsheets, a WMS uses technology to give you a clear, real-time overview of your entire inventory

Efficient Warehouse Operations

The system tells you the best place to store new products based on available space and demand

What do we offer?

Whether you’re a growing e-commerce business or a busy distributor, a WMS can transform your operations. By automating manual tasks and providing real-time visibility, you can reduce costs, minimize errors, and deliver a better experience to your customers.

Multi Warehouse

Easily create and manage purchase orders to suppliers. Keep track of incoming stock, expected delivery dates, and supplier performance in one place.

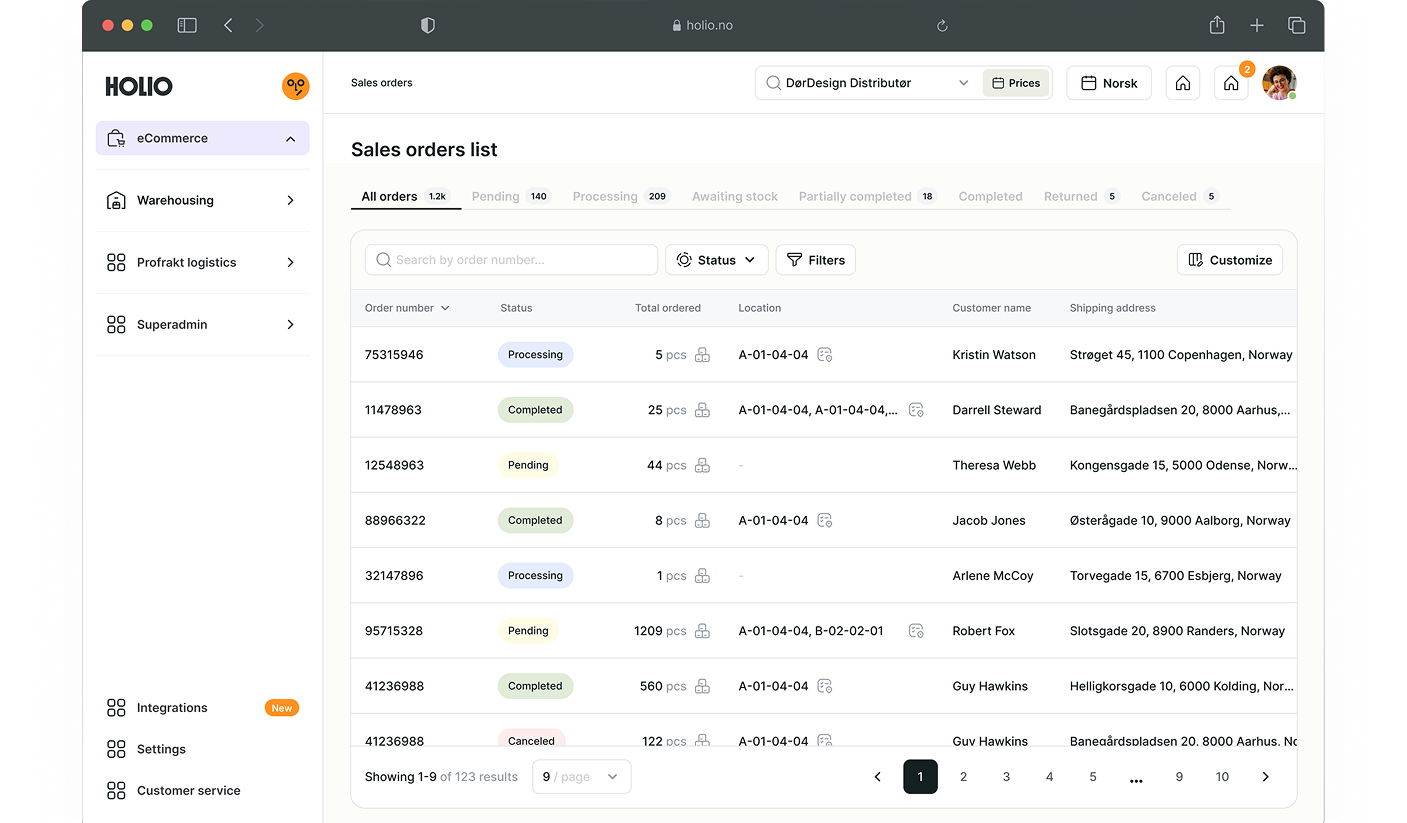

Sales Orders

Handle customer orders from start to finish with full visibility. Automate order confirmation and fulfillment to improve operational efficiency.

Products

Centralize all product data, including variants, SKUs, and pricing. Make it easy to maintain consistency across your systems and sales channels.

Locations & Inventory

Monitor inventory levels across multiple warehouse or store locations. Get a clear overview of what’s available and where – in real time.

Return Portal

Simplify the returns process for both your team and your customers. Manage return approvals and restocking workflows with minimal manual work.

Integrated Transport Administration

Use your own carrier agreement or seamlessly set up Profrakt shipping directly within the platform.

What is a Warehouse Management System (WMS)?

Think of a WMS as the smart brain of your warehouse. It's a software system that helps you manage everything inside your warehouse, from the moment a product arrives until it's shipped out to a customer.

Instead of relying on paper lists or complex spreadsheets, a WMS uses technology to give you a clear, real-time overview of your entire inventory. This means you always know exactly what you have, where it is, and when it needs to be sent out.

How Does a WMS Make Your Life Easier?

1. Better Inventory Control

No more guesswork:

You get an exact count of every item in your warehouse.

Real-time updates:

When a product is sold, the WMS updates your stock levels instantly. This prevents you from selling items you no longer have.

Easy tracking:

You can see where every single product is located, down to the exact shelf or bin number.

2. Faster & more accurate Order Fulfillment

Optimized picking:

The system guide your staff with the most efficient route to pick items for an order, saving time and effort

Reduced errors:

It uses scanners and digital lists to ensure the right product is picked every time, leading to fewer returns and happier customers.

3. Efficient Warehouse Operations

Smarter receiving:

When new products arrive, the WMS tells you the best place to store them based on size, popularity, and shelf space.

Organized shipping:

It helps you prepare shipments and creates all the necessary paperwork, like shipping labels and packing slips, with a single click.